Warehousing solutions built for performance, agility, and scale

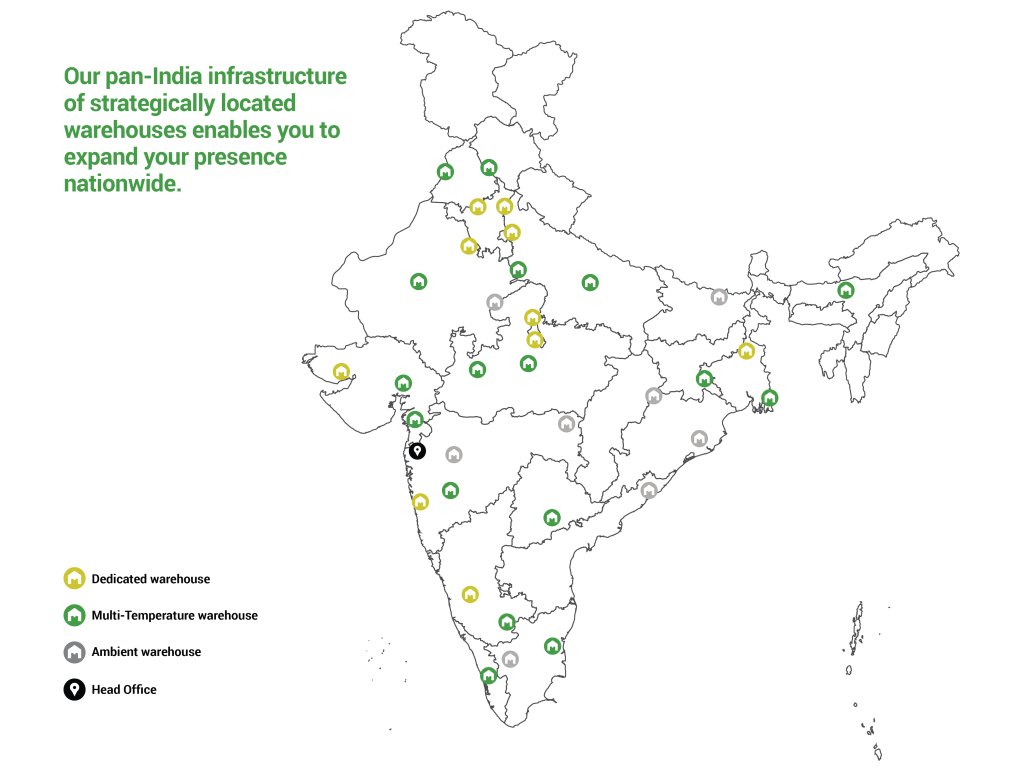

Address consumer demands throughout India

Our strategically located 35+ warehouses enable businesses to penetrate new markets. As a controlled cost fulfilment solution, our warehousing solutions enable enterprises to consolidate orders and distribute them in multiple locations, resulting in a better cost-to-serve ratio and fewer road miles due to higher drop densities. The nationwide presence of our multi-temperature warehouses spanning 1.3 million sqft of space offer a perfect solution for food brands to scale their business through the urban and rural landscape of India.

Maximize operating performance with unified way of working across warehouses

To inculcate a uniform way of working our proprietary technology UnitXPro was embedded in the way our warehouses perform. UnitXpro ensures business continuity, boosts productivity and efficiency, streamlines operations, and builds business intelligence while empowering a culture of co-creation. It improves various functions, processes, and systems, of a unit including proactive management of contingencies while making sure that no sales are lost due to equipment or personnel concerns. The technology also enhances and simplifies all system procedures consequently reducing risks across functions.

Improve efficiency and productivity of business units at lowest system costs

We help achieve efficiency at warehouses by optimizing space utilization, streamlining operations, and increasing productivity. Our processes are planned to balance inventory storage and turnover. The state-of-art infrastructure we have helps smoothen pick-up, racking, and other processes. We train people with industry best practices to improve productivity in our operating environment. We constantly focus on leveraging technology to further improve the effectiveness of our people and processes.

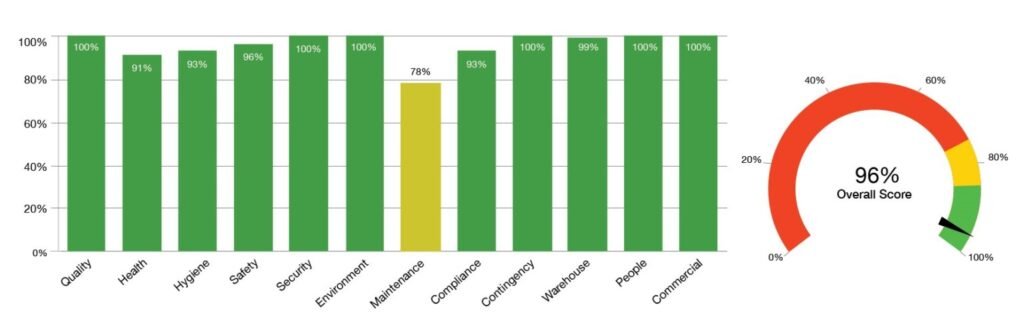

Assured quality, safety, and hygiene compliance

Safety and quality are a part of our DNA given product integrity are of the highest value in the foodservice domain. Our entire team supports this belief, and as a result, a specific internal audit was created to ensure our quality. SQVI (Service Quality Value Index) is the internal process Quality audit designed on the Food Safety Principals which are derived from various International and National Food Safety Authorities and Legal Authorities. It improves 13 quality and other aspects ensuring efficient and effective operations to deliver brand protection and business continuity. We further this process by awarding an internal rank to our best-performing units by a process called UPVI (Unit Performance Value Index). All of our units strive towards operational excellence. To measure each unit’s performance, we created UPVI which is an index that measures customer-centricity, safety, quality, operational execution, and innovation.

Range of solutions to serve you better

With our extensive knowledge of the foodservice industry, we aim to empower brands in the culinary domain with various warehousing offerings to streamline processes that construct the backdrop of their business. Our warehouses are FSSAI certified, equipped with the modern G+4 pallet racking system and other product handling equipment’s like battery operated forklifts and reach-trucks.

Shared Warehouses

We help multiple businesses manage their warehousing needs by storing their inventories at a multi-client warehouse that acts as a distribution center. With collaborations on space, labor, and technology costs help improve supply chain operations to run more efficiently.

Dedicated Warehouses

We assist businesses in managing dedicated storage facilities. We bring in our people, processes, and technology to manage different kinds of inventories and enable the supply chain lifecycle to thrive, so their stakeholders can concentrate on customer satisfaction.

Automated Storage and Retrieval (ASRS)

ASRS is a type of warehouse automation technology meant to buffer, store, and retrieve products and inventory on demand. ASRS provides several substantial benefits to operations by automating the low-value and repetitive job of inventory storage and retrieval.

Temperature controlled

Our climate-controlled warehouses can range from humid environments for storing fresh fruits, flowers, and other perishables to freezers for storing frozen items. These warehouses help maintain the temperature and integrity of the products stored in cold storage.

Ambient / Dry

Our dry warehousing solution is concerned with the storage of consumer products including packaged food. With this kind of warehousing, we offer an excellent alternative for products that require quality and safety but do not require precise temperature control.

Value-added services (VAS)

We tailor-made VAS allows you to focus on your core expertise. Some of our flexible solutions include – Packaging, Bundling, Breakbulk operations, Cross docking, Compliance Advisory and Execution, Network Design & Re-Design, Material Sourcing and others

Leverage our warehousing capabilities to your competitive advantage

Together we can achieve these warehousing outcomes

Optimized Inventories

Improved order accuracy

Efficient Space Utilization

Streamlined Process

Resources

Transforming Waste into Wealth: Bio-Diesel Innovation for a Leading QSR Chain

Discover how a leading QSR chain transformed its sustainability challenges into opportunities by converting used cooking oil into bio-diesel. This...

Read MoreProactive or Paying the Price: The Cost of Ignoring Predictability

CategoryThought Leadership February 26, 2024 [Avg. Read Time = 4 mins.] Amidst the daily hustle, a small yet popular bakery...

Read MoreImpact of ESG on Food Supply Chain Sustainability

Imagine a future where your food supply chain goes beyond just being fast and cost-effective, to also being green, fair,...

Read MoreWomen Leadership in Supply Chain

Food Supply Chain Leadership Forum’ is an initiative by Radhakrishna Foodland aimed at creating an exclusive engagement platform in the Indian...

Read More